Concept to Delivered Goods

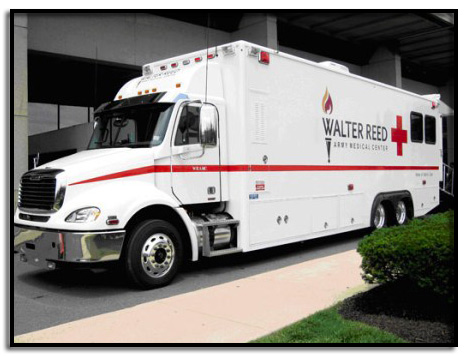

General Truck Body Manufacturing Company of Houston, Texas has developed the Patient Evacuation Vehicle (PEV), a first-of-kind vehicle that rapidly matured from concept to first production unit in less than one year. The configuration of the Patient Evacuation Vehicle (PEV) includes a unique combination of best-in-class systems equipped on ambulances, buses, clinical, rescue vehicles including aircraft. The Patient Evacuation Vehicle (PEV) is based upon a modified tractor chassis equipped with a first-in-class full air ride suspension and an on-the-fly hydraulic PTO system. The vehicle is equipped with a host of operator controls and features, including radio communications and NFPA compliant emergency lighting and siren systems.

General Truck Body designed and integrated their custom body solution onto the tractor chassis, creating a robust clinical environment for both the patients and medical team. The body includes a special walk-through feature that provides unobstructed access to the driver’s cab from the patient area and a custom rear entrance ramp which facilitates clear and safe handling of litter-borne critical care patients. The Patient Evacuation Vehicle’s (PEV’s) sub-systems include redundant & intelligent electrical power generation and distribution systems, integrated heating and cooling systems, medical grade oxygen, air, suction delivery systems and a variety of other clinical features and capabilities.

Custom Interior

Build to Specifications

The Patient Evacuation Vehicle (PEV) is equipped to transport up to

• twelve (12) ambulatory patients

• sixteen (16) litter-borne patients

• four (4) medical team members

• one (1) driver

• and one (1) assistant

There are a total of thirty-four (34) secure occupant positions within the vehicle. Special seating with a fold-up feature provided for both ambulatory patients and medical team members that improves access for safe handling of litters in the patient compartment. Litter–borne patients are secured for transport using four (4) litter stanchions and were modified for vehicular use and are mounted on special vibration isolators integrated into the structural members of the pallet and the vehicle’s body. The pallet isolation feature further reduces road vibration and harshness subjected to the litter-borne patients.